ball nose end mill feeds and speeds

Give G-Wizard a try for your ball nose feeds and. Spiral geometry insures efficient debris removal.

Model Engineering And Engineering Tools Online From Rdg Tools Ltd Home Page Engineering Tools Tel 01422 885069 884605

Choosing the Right Ball Nose End Mill Cutter.

. In the process of manufacturing molds a tool called a ball end mill with a circular cutting edge is often used. We have listed these also as individual recommendations. From the chart chip thickness is 0005 and all of our ball nose finishers have 2 flutes.

Actual speeds and feeds will depend on many variables such as rigidity workpiece hardness tool extension machine. Ie- 6037 x 0005 x 2. Excellent choice for unattended finish milling at small depth and high speeds and feed rates.

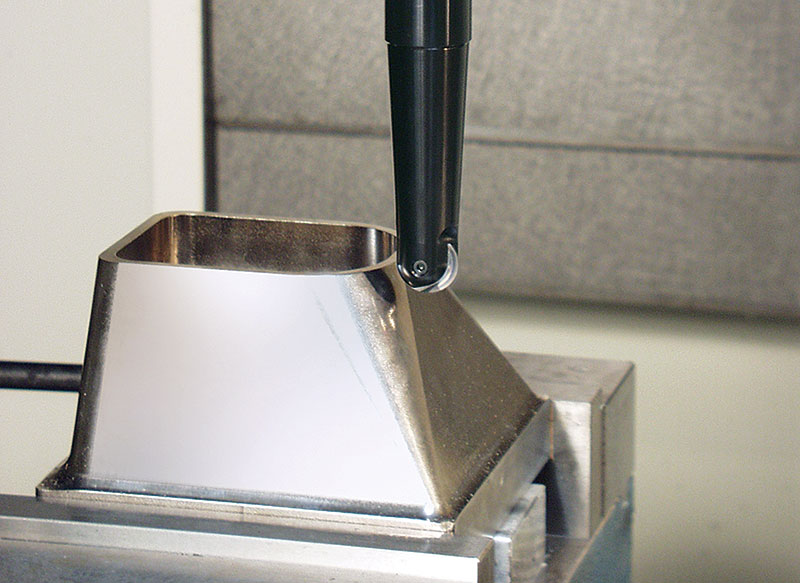

The parameters provided are suggested operating parameters. Using the same criteria as the spindle speed calculation RPM 6037. If possible it is highly recommended to use ball nose end mills on an incline ß to avoid a 0 SFM condition at the center of the tool thus increasing tool life and part finish.

The machining of three-dimensional contour forms such as those. Cutting edge geometry virtually eliminates chatter at high feed rates. 60 Helix End Mill.

Choosing cutting parameterscalculating cutting speed and feed inch for ball nose inserts cutting parameters cutting speed amp feed table 1 cutting conditions for using steel shank holders. For milling of gray cast iron with or without coolant at medium feeds and speeds. Choosing Steel End Mills.

The Uses of a Metric Ball End Mill. The radial DOC is 05 axial increase from 05 to 25 3000 rpm at 002 Feed per tooth 3 flute SC 5 ball endmill brand. With better heat and wear resistance than high-speed steel these cobalt steel end mills can run at higher speeds and provide better performance on hard material such as iron hardened.

Use a Corner Round End Mill to Round Off the Outside. Below you will find downloadable and printer-friendly Speeds Feeds for each one of our products. Adjust speedsfeeds and width of cut to pull enough heat in chip.

Certain high performance end mills have very specificc running parameters relative to their material families. Precision ground harder grade for semi-finish and finish milling. Ski-Carb solid carbide end mills for aluminum non-ferrous applications come with patented design features that allow for corner milling without chatter greater shearing ability increased.

The problem comes from trying to plunge cut with the ball nose. I am creating a new calculator based on your feedback. 53 rows CC Square Radius and Ball Nose End Mill.

Ball nose tip provides step-free contour milling of 3D solid models. All posted parameters are suggested starting values that. Please fill out the form below with feeds and speeds that work for you and I will place them into a new database for.

Fine Pitch Rougher with 35 High Helix for Aluminum. You can carve with just the tip to get great detail and smooth contours or they can move a lot of. MB Ball Nose Insert.

Carbide Ball Nose End Mill Speeds And Feeds With advanced technologies and facilities strict good quality manage reasonable rate superior assistance and close co-operation with. Chips should maintain color blue purple etc Always use caution and best judgement when applying updated. And there is a Surface Finish mini-calc to help you determine scallop size calculations.

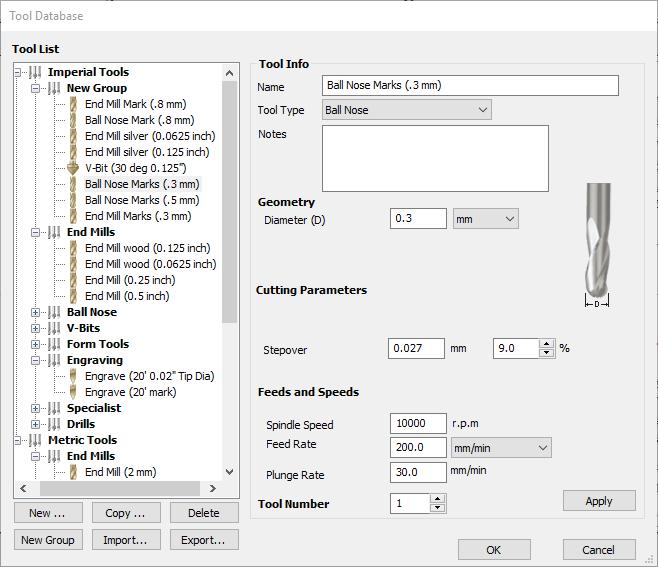

For example ball noses are a tip type for end mills. Speeds Feeds Library.

Feeds Speeds Shapeoko Cnc A To Z

Geometry Of Ball End Mill Cutter And Milling Process Download Scientific Diagram

Solid Carbide 2 Flute Tapered Ball End Mills Sdk Tool Supply

Discontinued Spetool 5pcs M03003 4 Flutes Carbide End Mill Ball Nose

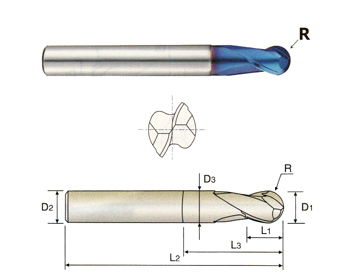

Short Cutting Edge 2 Flutes Solid Carbide Ball Nose Cutting Tool China End Mill Milling Cutters Made In China Com

Gm 4bl R6 0 R7 0 Cemented Carbide Higher Feed Speed Machining Efficiency 4 Flute Ball Nose End Mills With Straight Shank Tools End Mills Ball Nose End Millsball Nose Aliexpress

Conical Tool Speed Feeds Tapered End Mills Cutting Tools

Carbide End Mill Feeds And Speeds Explained Sctools

Indexable Mills Speed Cavity Cutting Modern Machine Shop

Basic End Mills Technical Information Msc Industrial Supply Co

Recommended Cutting Conditions Ball Technical Information Tools For Machine Processing Tools Misumi Vona Comprehensive Web Catalog For Misumi

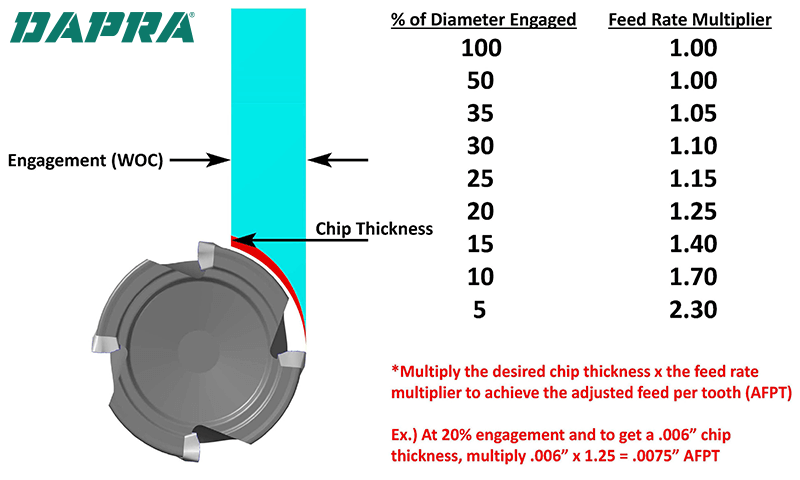

Ball Nose Finish Milling Reference Troubleshooting Info Dapra Corporation

Micro End Mills 0 2mm 0 5mm Feed Speed Nomad Carbide 3d Community Site

Highly Efficient Fxs Carbide Ball Nose End Mills Vol 3

Common Formulas For Milling Operations Speed Feed Sfm Ipt Mrr Dapra Corporation

Hpmt Provides Comprehensive And High Quality Range Of Solid Carbide End Mills